3D Printing

Find out more about our manufacturing processes below

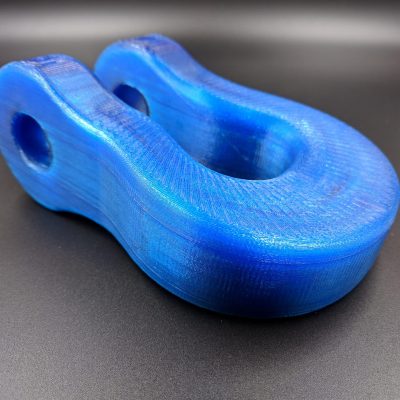

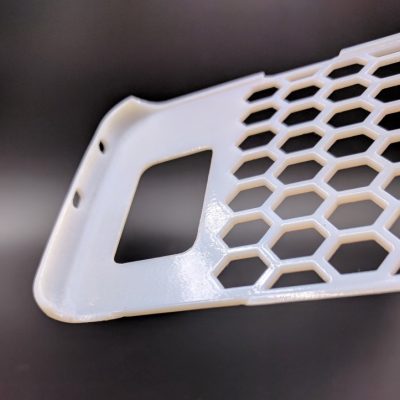

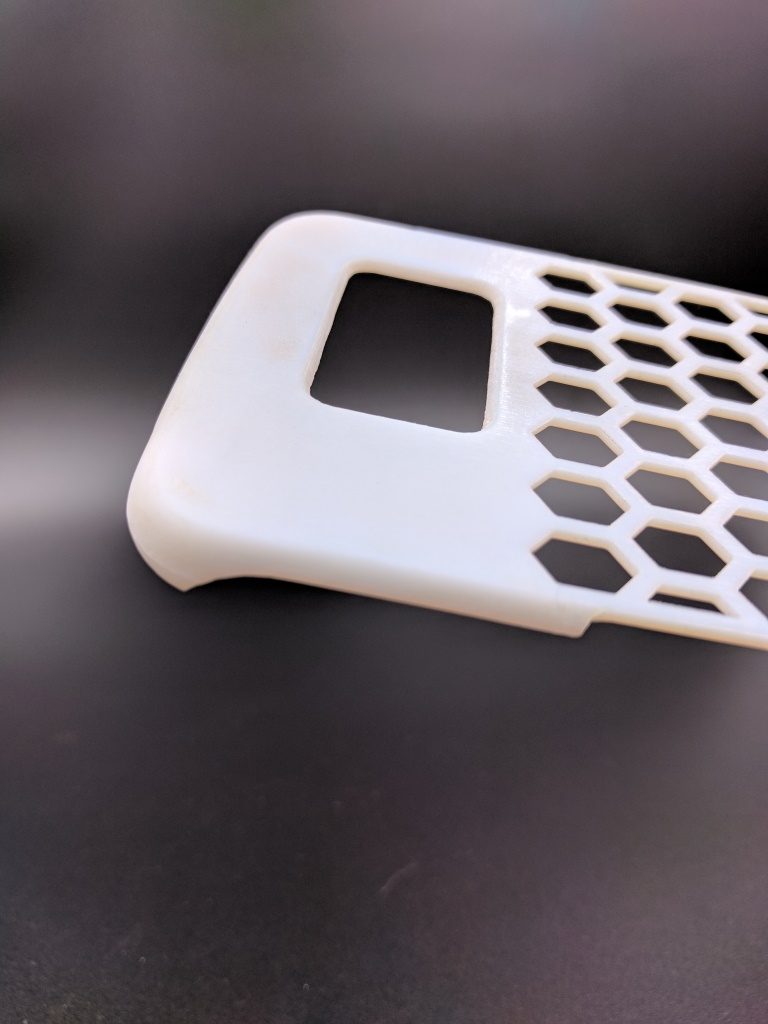

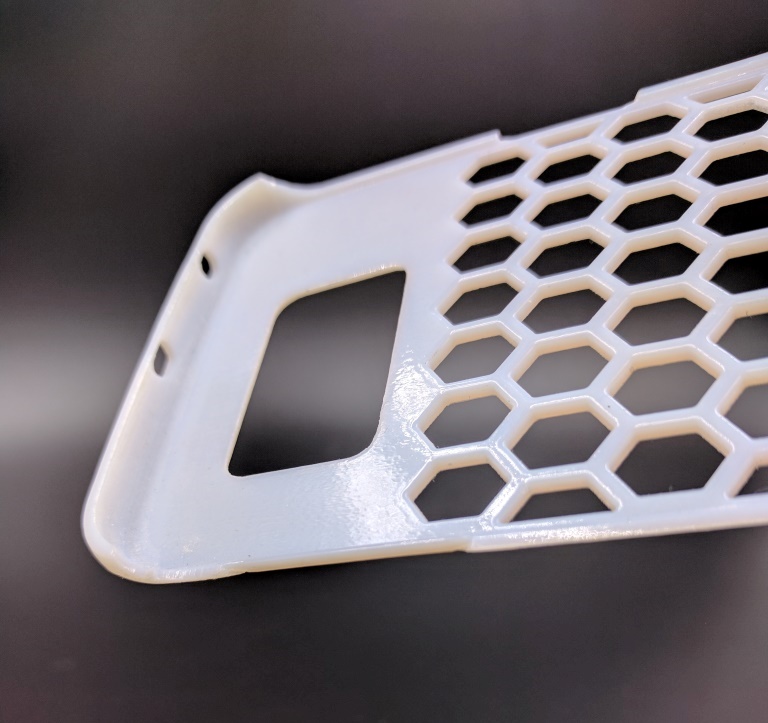

FDM

Fused Deposition Modelling

ABS

A general engineering plastic widely used in industry. This is our most common 3D printing material.

As it can be joined with solvent there is no limit to the effective parts size. i.e. part can be much bigger than the printer build capacity.

- End Use

- Temperature Resistance: 80deg

- Low Creep

- Good mix of strength and flexibility

- Outdoor Safe – Medium term, painted long term

- Large Colour Range

- Waterproofing Possible

- Economic

- Not Food grade plastic

PLA

PLA is mostly used by our customers for the Metal casting industry that is for “lost wax” or “investment casting”

PLA is long term biodegradable, made from corn starch. This makes it ideal for burning out cleanly when used for investment casting.

- High Stiffness

- Low Creep

- Large Colour Range

- Economic

- Temperature Resistance: 35deg

- Not recommended for end use parts

- Not outdoor Safe

- Failure mode: Brittle

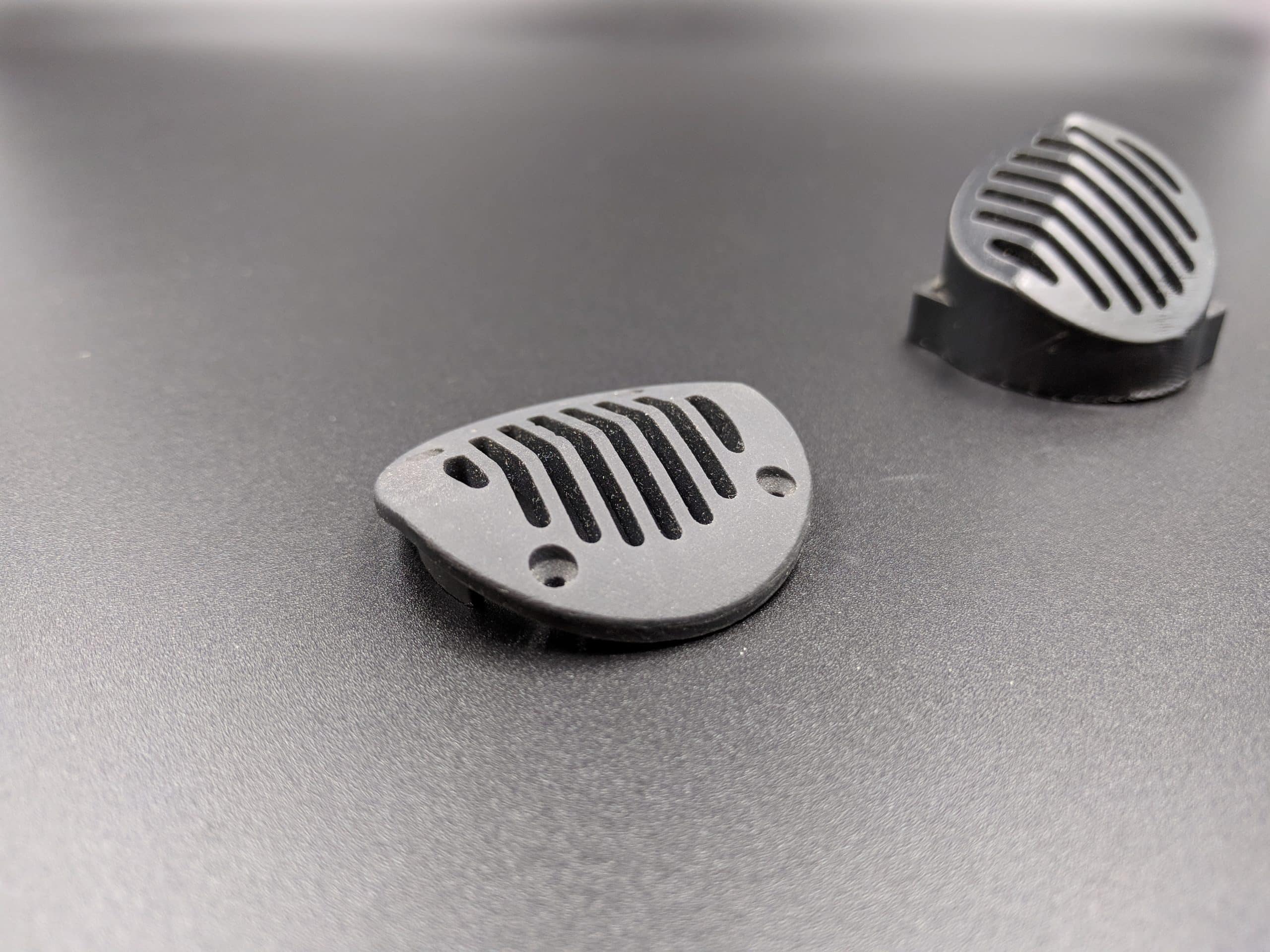

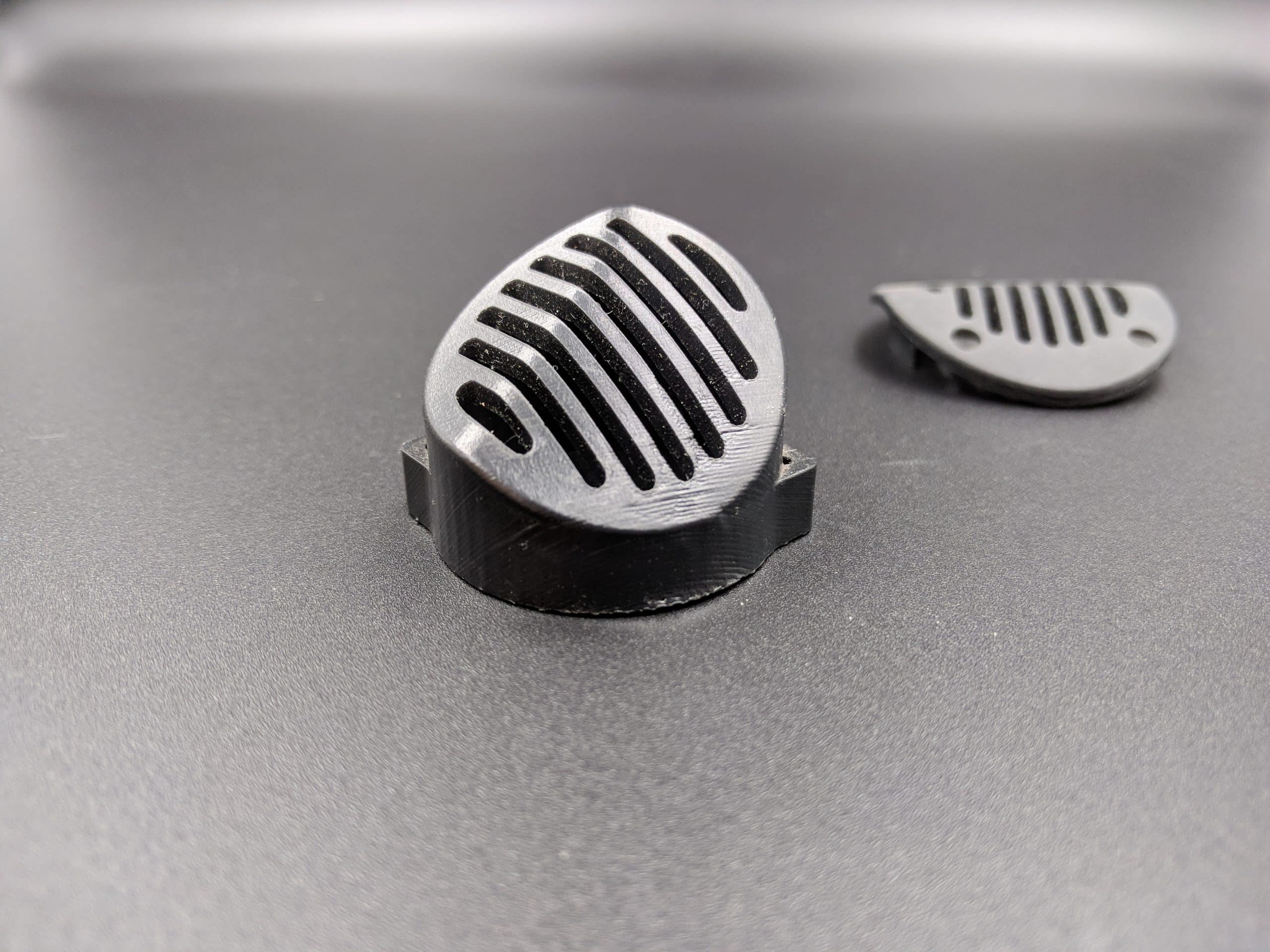

Flame Retardant ABS

This ABS is mixed with a flame retardant additive, creating self extinguishing parts if fire safety is an issue. The surface finish is lower quality than normal ABS, however it can be bead blasted to a smoother matte finish.

The two colours available are off white, and black.

- End Use

- Outdoor Safe

- Temperature Resistance: 80deg

- Waterproofing Possible

- Limited Colour Range

- Rough Surface

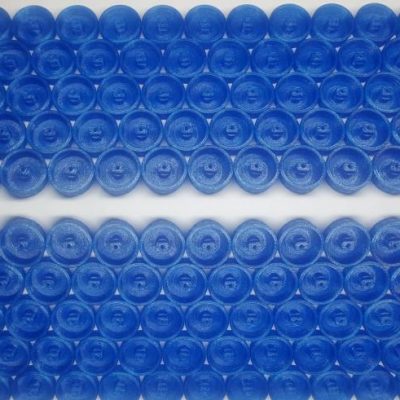

PETG

PET is a useful material if you are looking for high volume production runs of relatively simple or large parts, it can be more economic than ABS in this case but it depends on geometry.

The material is quite robust, for example coke bottles are made from PET

- End Use

- Temperature Resistance: 55deg

- Low Creep

- Outdoor Safe for medium term use

- Large Colour Range

- Economic for large production runs with simple geometry

- Waterproofing not possible

- Solvent joining not possible

- PETG material is food safe however FDM is porous, so not recommended for food safe applications

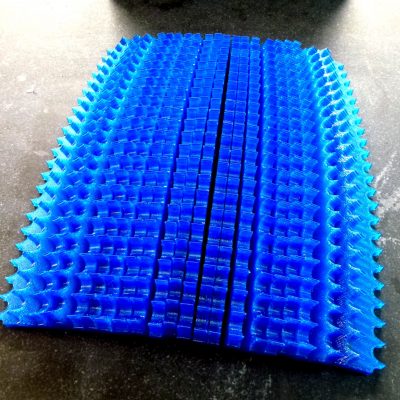

ASA

Very similar the the most common FDM material- ABS. Except ASA is UV stabilised and can handle being used outdoors for long periods before becoming brittle.

ASA can be solvent sealed, meaning parts can be made waterproof if desired. There is also a wide range of colours available. Check out the quoting page for all the available colour options.

- End Use

- Low Creep

- Outdoor Safe

- Large Colour Range

- Waterproofing Possible

- Temperature Resistance: 80deg

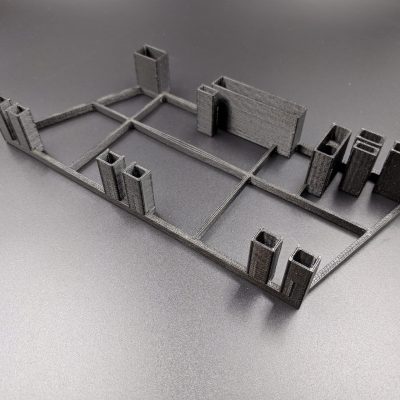

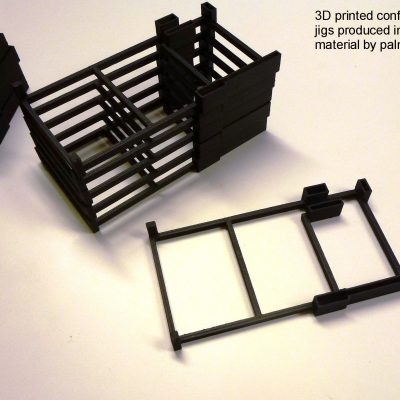

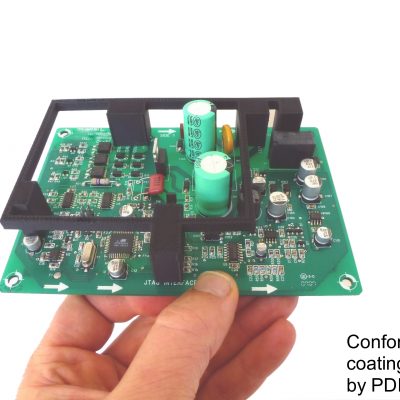

ESD – ABS

Electrostatic Discharge Safe (ESD) Materials are semi-conductive, these materials are used especially in electronics manufacturing for jigs and fixtures. Our ESD ABS is a high grade material that gives the correct resistance for Electrostatic dissipation.

Use ESD – ABS for water based conformal coating, See our ESD – PET material for Solvent based coatings

- Water based coating compatable

- High Stiffness

- End Use

- Low Creep

- Temperature Resistance: 80deg

- Not Solvent based Conformal coating compatible

- Colour Range – only Black

- Not food grade plastic

ESD – PET

Electrostatic Discharge Safe (ESD) Materials are semi-conductive, these materials are used especially in electronics manufacturing for jigs and fixtures. Our ESD PET is a high grade material that gives the correct resistance for Electrostatic dissipation.

Use ESD – PET for Solvent based conformal coating, See our ESD – ABS material for water based coatings

- Solvent based coating compatible

- End Use

- Low Creep

- Temperature Resistance: 50deg

- Colour Range – only Black

- Not food safe

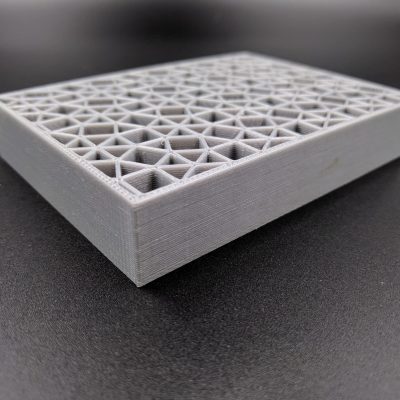

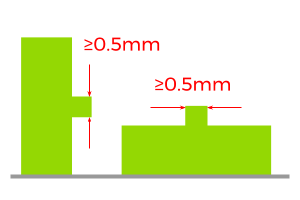

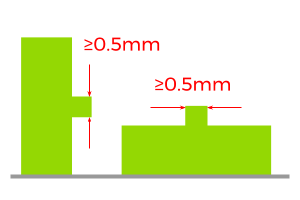

Thickness

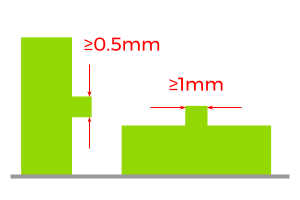

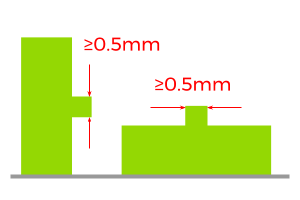

Feature Thickness:

In the vertical (z) direction, features should be kept above 0.5mm thick, but ideally above 1mm. horizontally features should be thicker than 1mm or they will not print.

Wall Thickness:

Wall thicknesses should ideally be 1mm, 2mm, 3mm, etc. (rather than 1.5mm, 2.5mm, 3.5mm etc.). These thicknesses are most efficient for our nozzle sizes.

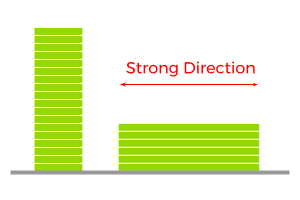

Orientation

The orientation of the part being printed effects both the surface finish, resolution, and strength of different features of your part.

Parts are prone to breaking along layer lines, however, our industrial heated chamber printers ensure that inter-layer bonding is much stronger than desktop FDM printers.

If you want your part to be strong in a certain direction and are unsure how to orientate it, just pop a comment on your object describing the application and we’ll orientate it for you.

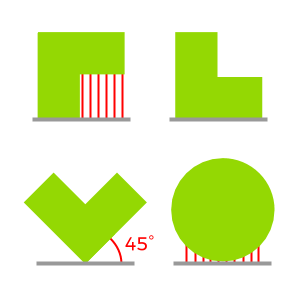

Overhang

Overhanging features of your part require support when printing. The printer will create a break-away structure underneath, which is later removed. Sometimes where the support touches the part, the surface finish is affected.

When designing a part for FDM printing, use overhang angles of 45 degrees and above where possible to reduce the necessary support. Your parts will be cheaper, look cleaner, and print faster.

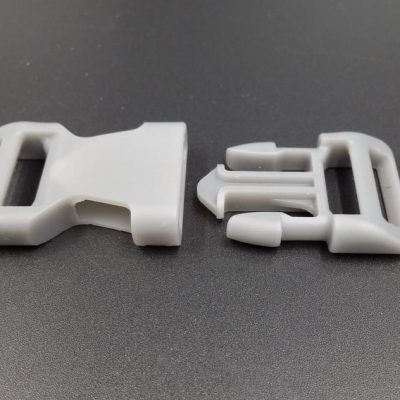

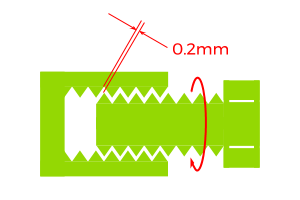

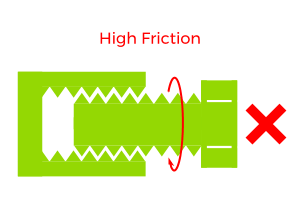

Clearance

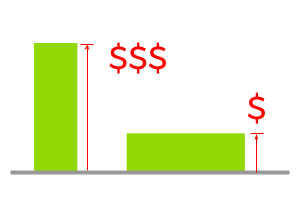

For moving parts, threads, and other joints we recommend 0.2mm clearance so that parts fit and slide together.

For press fits, size for size works well in most applications, otherwise a light sand often fixes any issues.

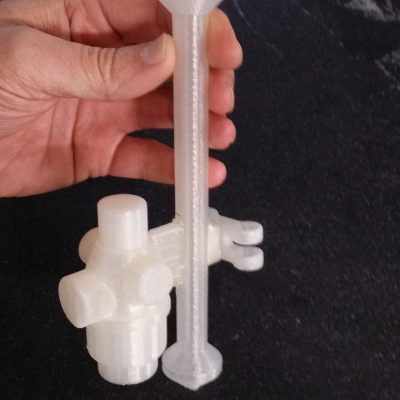

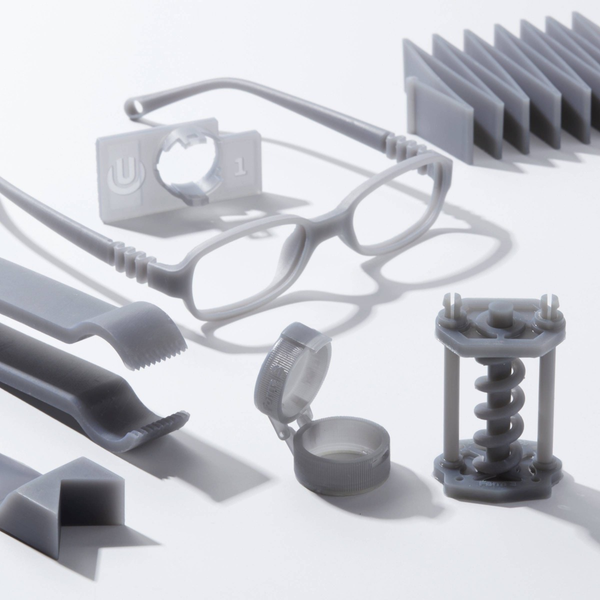

SLA

Stereolithography

General purpose SLA resin

This is our most economic material, it comes in three colours: black, white, and semi-transparent. The clear when polished, becomes almost glass-like. This material is similar to acrylic and will be suitable for many prototyping applications, it is however more brittle than our ABS like and glass filled material

- Medium Stiffness

- Temperature Resistance: 80deg

- 3 colours

- Economic

- Not food safe

- Can be brittle

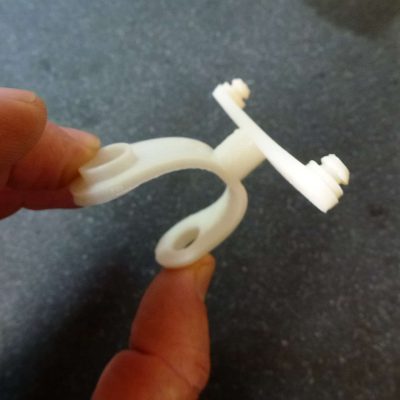

Tough 1500

Tough 1500 Resin for stiff and pliable parts that bend and spring back quickly.

Prototypes that repeatedly bend and quickly return to shape, jigs and fixtures requiring repeated deflection, simulating the strength and stiffness of polypropylene (PP)

Tough 1500 Resin is certified safe for skin contact, also making it an ideal material for wearables, personal protective equipment, and other consumer goods.

- Temperature Resistance: 52deg

- High elongation before break

Tough 2000

Choose Tough 2000 Resin for prototyping strong and sturdy parts that should not bend easily. Strong and stiff prototypes Jigs and fixtures requiring minimal deflection Simulating the strength and stiffness of ABS

The “2000” in the name represents the material’s tensile modulus. If you need a less stiff material, try Tough 1500 Resin or Durable Resin.

- Temperature Resistance: 60deg

- High elongation before break

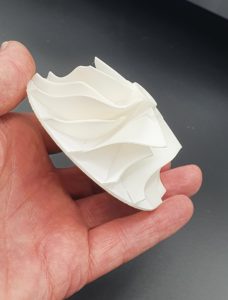

Glass Filled

A great SLA material with high stiffness and amazing toughness.

This is a very useful material (and our most popular) it’s like a glass filled ABS and has good surface finish.

It holds its shape better that general purpose SLA materials, that can move out of shape in transit if there are thin walls over large spans.

- High Stiffness

- Low Creep

- Temperature Resistance: 55deg

- Not food safe

Ridgid 10K – (ultra glass filled SLA)

This is a impressive SLA material, heavily glass filled for even more rigidity than our “rigid 4000” material.

This material can be post treated to increase stiffness and temperature resistance up to 200 degC (depending on forces involved)

This is a very useful material when you need something rigid and temperature resistant.

- High Stiffness

- Low Creep

- Temperature Resistance: 200deg

- Not food safe

High Temp

This resin holds it’s shape in high temperature environments, perfect for small test jigs and fixtures or even mold tooling for small runs. With an incredible temperature resistance for an SLA material.

- High Stiffness

- Temperature Resistance: 200deg

- Low Creep

- Colour Range – only semi transparent

- Brittle

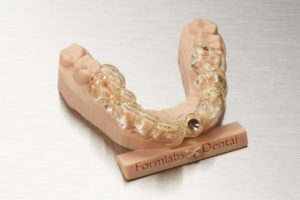

Surgical Guide -Dental SLA

Designed for dental drill guides but can be used for many medical device prototypes Can be steam Autoclaved, see full specification here

- High Stiffness

- Temperature Resistance: 120deg (short term)

- Food safe

- Can be brittle

Painted

SLA parts can be painted with any pantone colour of your choice. This not only improves your parts visually, but also increases their lifetime as the paint blocks UV light from turning the plastic brittle over time.

Thickness

Feature/Wall Thickness:

Features and walls should be kept above 0.5mm thick. They can be made thinner, however, due to the brittle nature of SLA resins, they will be prone to snapping.

Clearance

It is not recommended to use SLA materials together as moving parts as the material binds to itself easily. However with a clearance of 0.2mm or greater and some grease, parts do move well enough for demonstration purposes.

Multijet

Multijet (or Polyjet) Printing

Thickness

Feature/Wall Thickness:

In any direction (x, y, z) features should be kept above 0.5mm thick, below that the walls occasionally don’t appear in the print. Even if they do appear, the clean up process can be rough and thin features may break.

Orientation

Polyjet parts are homogenous, so the orientation doesn’t affect strength like it does for FDM parts. However it does affect print time and cost.

The print head sweeps back and forth depositing a whole layer of plastic each sweep, so flat and wide is faster than tall and skinny. Our quoting software optimises your part orientation for the lowest cost.

Clearance

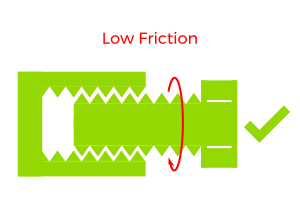

Polyjet materials are naturally slippery, making this process a great choice for fitment testing.

It is still recommended to give threaded or moving parts 0.2mm clearance for best results.

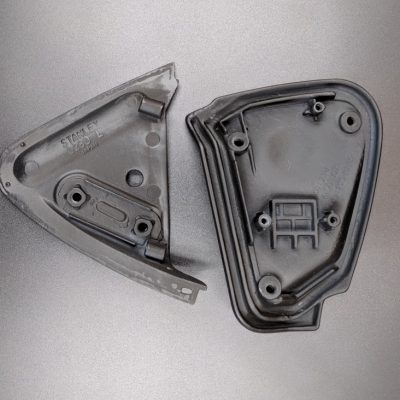

Vacuum Casting

Two-part Resin Casting

Polyurethane

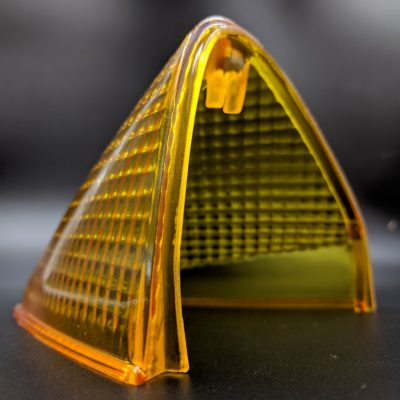

The vacuum casting we offer for rigid parts always starts with a polyurethane base. Usually it’s mixed with additives to change it’s properties, however it is possible to use plain polyurethane which gives a translucent finish as seen on the left.

The great surface finish and strength makes vacuum casting a perfect choice for final prototypes, prior to injection moulding or low volume production.

- High Stiffness

- End Use

- Low Creep

- Large Colour Range

- Waterproof

- Temperature Resistance: 60deg

- Economic

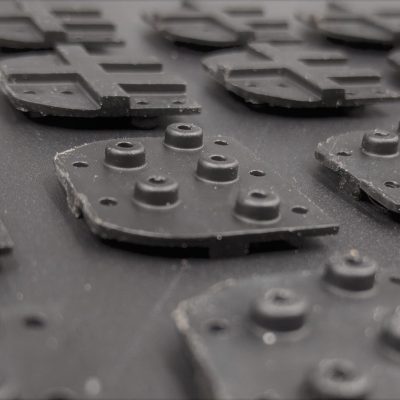

Nylon Glass Filled Urethane

This is our strongest vacuum cast material, very high stiffness and the same surface finish as any other vacuum cast urethane.

This has been used for physical testing to validate parts before moulding in real glass filled nylon.

- High Stiffness

- End Use

- Low Creep

- Large Colour Range

- Waterproof

- Temperature Resistance: 80deg

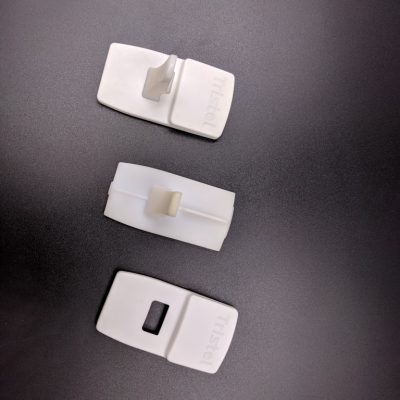

Silicone

We frequently cast silicone parts for custom seals and gaskets, but there is a wide variety of hardness’s available. Anything from the softness of a jelly baby right through to the hardness of a car tyre, (Shore 30 – 95A hardness)

The level of detail matches that of an injection moulded part.

- End Use

- Low Creep

- Large Colour Range

- Waterproof

- Temperature Resistance: 60deg

Raw

Vacuum Casting gives a naturally smooth, matte surface finish on every type of polyurethane we offer.

Polished

A polished surface is necessary when parts need to be transparent, but also possible for opaque parts that need a gloss appearance.

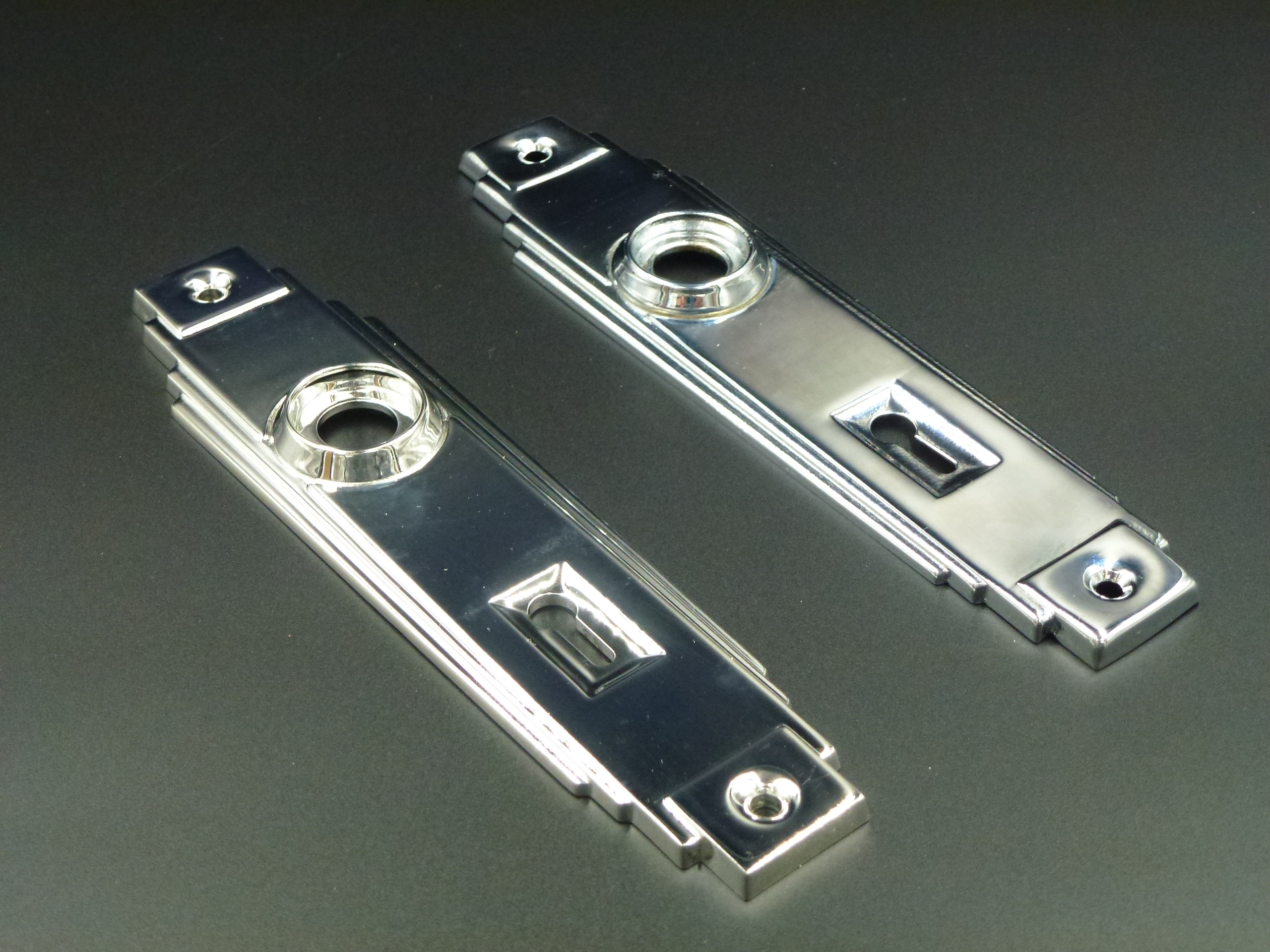

Elecrto-plating

Vacuum cast parts have a smooth finish and can easily be electroplated with chrome or various other metals.

Thickness

Feature Thickness:

In the vertical (z) direction, features should be kept above 0.5mm thick or they risk being snapped during the moulding process.

Wall Thickness:

Wall thicknesses should ideally be 1mm or greater for to ensure your parts don’t get damaged during shipment.

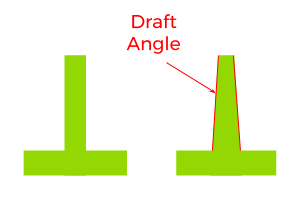

Draft Angle

Drafted surfaces aren’t a necessity for vacuum casting, however they are crucial for injection moulding which is a common next step.

Often drafted surfaces are tricky to implement into a model after it’s finished. So if you intend to go into production and eventually injection mould your product, we recommend considering drafting from the start!

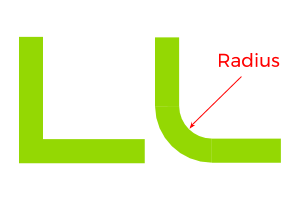

Radius

Again, this is optional for vacuum casting, but recommended if proceeding to injection moulding.

Corner radii allow plastic to flow through your mould better and are fairly easy to imlpement after a CAD model is finished.